Ann and Gord built what is called the “World’s Greenest Modern House” from the greenest building program ever created. Their cob – “mud” home includes energy and water conservation, composting toilets, solar photovoltaics, solar thermal: domestic hot water and heating, rainwater harvesting, living roofs, earthen floors and counters, natural non-toxic – no or low VOC finishes and food gardens.. all in an exceptionally beautiful yet really affordable home. Their motto is Less Life Stuff, More Life Style! ECO-Sense.ca

Ann and Gord met and were married within six month and a year later the couple bought 8 acres on Canada’s Vancouver Island, sharing the purchase with Ann’s parents, moving everyone including Gord’s two young children and a border collie into a small trailer on the land.

They wanted to build a home that was as sustainable as the building code would allow but also wanted to push the current sustainable building policies and boundaries. The original intent was to build a straw bale home but the more they read about cob the more they liked it.

They wanted to build a home that was as sustainable as the building code would allow but also wanted to push the current sustainable building policies and boundaries. The original intent was to build a straw bale home but the more they read about cob the more they liked it.

The original site had been used as a garbage dump and was damaged. The couple planned to clean it up so it was better than new. Their goal was to build a multi-generational home that functioned within this, so that no line separated their dwelling from the rest of nature. They would share energy, resources and water and the eco system would be better off for it.

Ann and Gord do work shops on cob building and this is one of the creations

Normally you would design your house, altering the ground to fit the home design. Ann and Gord first consulted their engineer, looking at where he thought was a good location, then took a piece of graft paper and mapped it out. That determined the shape of the house, using nature as its architect. The nice thing about a cob building is that it is very fluid and allows a design to be worked backward in this way. The more shape and curves it has the stronger it is, similar to an egg shell.

The couple experimented with building a work shop before tackling the main house. This first cob building was mixed by hand. By the time they built the main home they found mixing by roto-tiller improved the efficiency by 500% and used minimal gasoline – just 25 litres – in the process.

There were road blocks on the build but the couple state that some of the best solutions were when they were trying to solve what they thought was a problem. This was when the best creativity came out. The couple never thought of themselves as creative, they were just trying to deal with the situation. Creativity just happened. The important thing was to complete the house in such a way was that they weren’t scared of trying something new or scared of making a mistake or even failure. The couple considered failure a learning opportunity.

The home took 20 months from start to finish. The couple did most of the research and building themselves but hired professionals and individuals as needed.

The Building and Thermal Mass

Ann and Gord grow their own vegitables and have a healthy garden fed by the grey water systems

The couple says that the lifespan of a conventional house is now only about 60 years, cob has an expected lifespan of about 500 years. Houses use a lot of valuable resources and energy. You are fighting nature all the way therefore we all win when a home is truly built to last.

The final home is a 2,150 square foot, five bedroom, two bathroom, two kitchen, cob building, that functions like a duplex but technically is not. The way their building inspector approached it is that they have a really big kitchen with a small hallway to separate the two halves. Ann and Gord and the two children live on one side of the home and Ann’s parents in the other.

The couples share utilities along with the phone, freezer and a washing machine. A little pass through window shows between the two kitchens make it easy for the two sides to converse. They live together, sharing a mud room entrance but have semi private living facilities.

The cob walls are almost two feet thick and are a solid mass. Ann and Gord say that even thought the cob may have a lower R value (R-1) it functions as a much higher one. Their walls perform like a R-24 wall and they have the research to prove it. The couple has data loggers measuring the temperature and humidity in the home as well as loggers outside. The difference is that they have analyzed their home as a system, not just one component. The building code looks at trying to measure components and to function at the individual components of a wall assembly.

Generally in a conventional wall assembly there is no thermal mass. There might be some gyprock but that is about it. Without thermal mass, when temperatures change from inside to outside there is no real gradient other than the insulation stopping that gradient. If that insulation were to soak up moisture – and in their area it has been known to happen, you change the way the vapor pressures are working on the wall. With a mass wall, you have a very gradual temperature grading, you don’t have any dew points in the walls making it function differently.

Glass blocks and south windows let natural light shine onto the countertops

The roof of the home is insulated with formaldehyde-free fiberglass and the floors have a R-12.5 rigid Styrofoam. The majority of the house has an earthen floor – clay, sand and straw, the same materials as the house. This consists of three to four inches of cob with Hydronics for heating in the floors as well as built-in benches. This has been finished with several coats of boiled linseed oil that soaks into the areas. Linseed oil is an oxidizing oil that becomes very hard. 2 coats of a hard wax follows. The couple uses Osmo (can also use Naturhouse), but find Osmo easier to work with.

80% of wood in the house is recycled and the cupboards are Gord’s first attempt at carpentry. An earthen counter tops these cupboards. Ann and Gord do courses on earthen floors and counters and have written a little booklet (english and french translation) on the method for their blog. When you are doing plasters you need to have your fibres short. This can be done by running through a weed wacker or a chipper, but the couple does it by running it through a horse. Yes, they use horse manure. Ann says I had gloves on and I was scared to touch it and I felt it was horrible and stinky when we first started, but you hear about people using different manures all over the world, you get used to it and realize that it is a really useful material. She now exploits the merit of using this pre-chopped mixture.

Cob

Ann and Gord’s living roof model showing the materials and the order they are installed.

A cob home is made out of clay, sand and straw, mainly dirt made into mud. The couple also added a locally mined pumice, giving additionals insulation to the thermal mass.

You take moist clay – pottery moist, and add the straw and sand, then mix it together. The consistency should be like cookie or bread dough. To build, you stack the mixture a handful at a time and it gives you a heavy dense wall system. The walls are just eyeballed as you build as you don’t use forms. If the walls seems a bit out of kilter a hand saw is used to shave it into shape. Each wall is built up to about eight feet high by about 24 inches deep. The walls are left to dry and once they dry additional shaping can take place.

The couple says they got used to the process so in time it was quicker as they had less shaping to do.

Clay and Moisture

A bonus with Clay is its ability to control moisture. Dried clay holds a moisture content ranging between one and six percent. This ability to hold moisture has allowed currently occupied European cob buildings to last as long as 700 years.

A 14% or greater moisture content in a material is an opportunity for insects to move in, above 20% then funguses can live. With cob’s lower percentage neither insects not funguses can survive and the clay becomes inert, like stone. The walls resist humidity problems, mold or condensation.

Humidity in an earthen home, even in really dry climates stays in the 50% mark, where 40% to 60% is ideal for human health. Above 70% is dangerous for humans. A conventional house with a vapor barrier has to have a lower humidity to prevent condensation, keeping the humidity down to 35% by humidifiers or dehumidifiers. This barrier means that you can’t equalize it or moderate the humidity. A cob house it is naturally monolithic so it is an air barrier all to itself. The walls work to keep the humidity at the ideal level.

The Foundation

A cob home is made out of clay, sand and straw, mainly dirt made into mud.

The home has a concrete foundation and a fabric form was used. The couple says the fabric form is “an awesome material to use”. Using fabric gives you less waste, less wood for forms and it is easy to make curves, something that saves time and money.

The concrete the couple used is re-enforced and has a high fly ash content (45%) which reduces the carbon content of the material. Traditional concrete uses Portland cement which has a heavy ecological footprint and fly ash reduces the amount of Portland. For every ton of Portland Cement there is a ton of carbon submitted in that building process. If you can take some of that Portland out you can replace it with other by-products of the cementing process, whether it be fly ash, silica fume, volcanic ash, pulverized Baker clay baker bricks. It takes longer to cure but it lasts much longer because it mineralizes different. More information on ECOsmart Concrete.

In essence if the couple had used regular concrete it would have been the weak point of the building, having the weakest life span. Using more Portland may have made the home stronger but it would not have lasted as long in their high seismic zone.

Pumice was also added to the concrete. This addition increased the insulation (R-Value) by 260%.

Engineering

The truth window shows the aircraft cable in the walls

Ann and Gord’s home is one of the first load bearing legal cob residence in North America, a feat that really pushed their structural engineer. The couple live in an earthquake zone and say the area is overdue for “the big one” therefore the building needed to be engineered to withstand a quakes force with little damage if any. Traditionally cob can withstand minor movement as the straw in the mixture works like mini rebar, the couple wanted their home to be even stronger.

They first poured the concrete foundation, adding aircraft cable loops sitting out of the edges every 2 feet. The cob walls are then built and when you get to the top you there’s a concrete bond beam that mirrors the foundation. The result is a reenforced concrete ring around the top of your cob. Then you come back and you sew it together by diagonal tension cables. It is engineered so if the foundation moves in an earth quake the cables get tighter, pull down tight and suck the concrete cap onto the cob. This puts the cob under compression, a feat which cob likes, stopping any deformity.

The cob walls were reinforced using a geotextile, normally used in bank stabilization, running a horizontal strip every 2 feet. If a crack should happen it will stay in that 2 foot strip and not continue past this point. You might see a crack on the surface but it won’t compromise the structure.

Milk paints

Created her own sustainable – non toxic milk paints for the original home

The wall are finished with a homemade milk paint. Ann did several experiments and written a little booklet on the process. She also says the process is not a secret and there a various books on the subject.She says that you can buy manufactured milk paints but is expensive, it ships a long way and has a carbon foot print so it is better to make it at home.

Ann says that she found it interesting that when she previously had paint cans they went into a a little tox corner in a garage or workshop. Now when the couples does plasters or painting she lets the non-toxic plasters go hard and they stay in the plaster shed. When you want to used them you add water and they are ready to go.

Milk Paint Recipe Links

Martha Steward Milk Paint Recipe

Earth Pigment Non-toxic Pigments, Mica Powders and Mediums

Milk Paint: The original Milk Paint FAQ

Bathroom

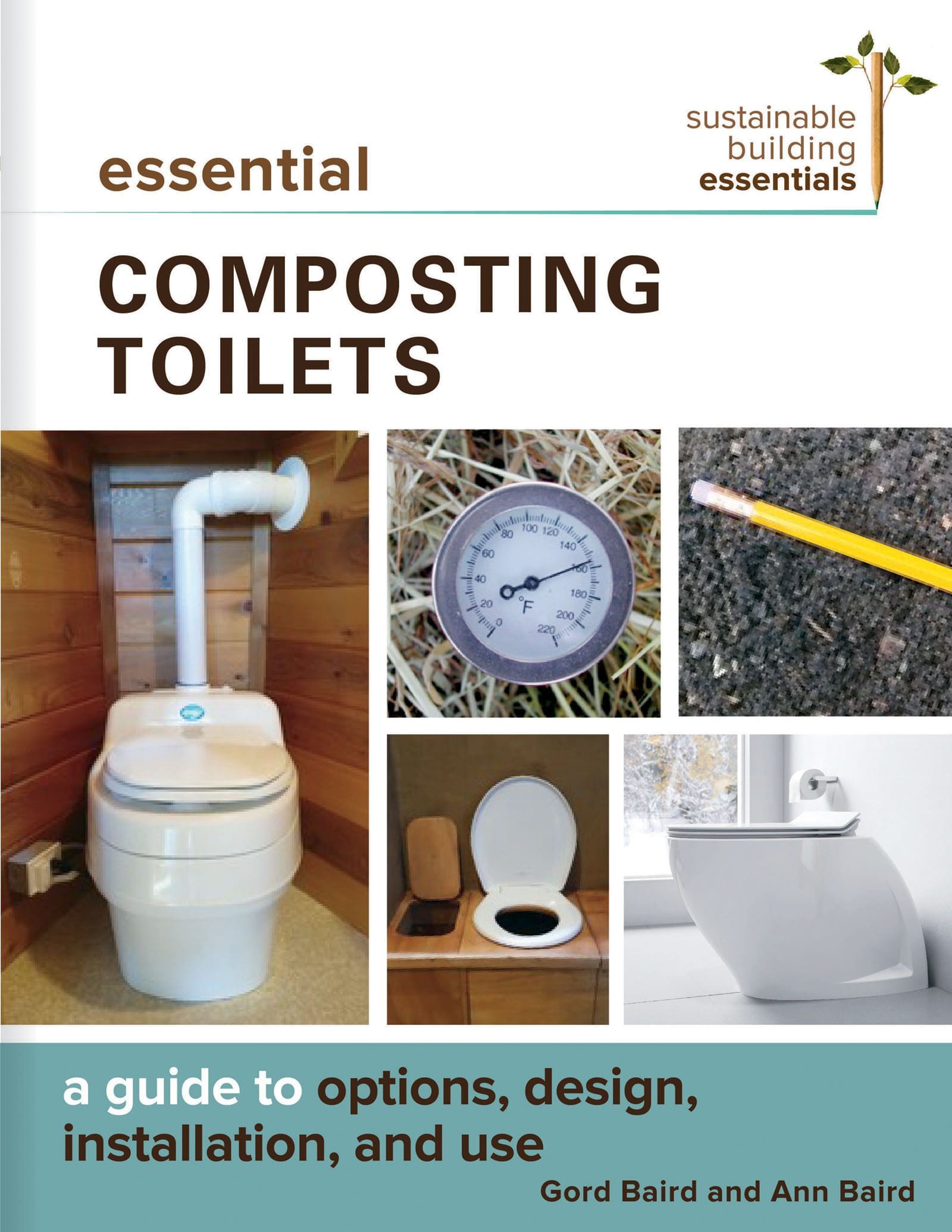

Ann and Gord’s composting toilet showing a box for shavings used instead of water for flushing

As you step into the bathroom you notice that once the door is shut a light comes on. The couple ran DC for all of their lighting and put a DC pin switch in. When the door closes the light goes on and it also allows for a little fan.

Bathrooms on both sides uses a composting system based on the Joseph Jenkins Humanure Handbook. It operates without water and the resulting “deposits” are turned into a rich, odorless compost.

The toilet has a cabinet with two – five gallon buckets inserted under the seat. Flushing is done by adding shavings to the bucket. Once the buckets are full – usually once a week – they are dumped into a compost area.

The toilet has a cabinet with two – five gallon buckets inserted under the seat. Flushing is done by adding shavings to the bucket. Once the buckets are full – usually once a week – they are dumped into a compost area.

In order to satisfy permit conditions the couple had to install a conventional toilet first. They flushed it once and then were able to take it out.

The bathroom also features a fan that has been positioned low so as to exhaust air and vapor but avoids sucking the warmest air out of the room. They say “having a high fan rather than a lower one is just the way it has always been done and not questioned.”

Bathrooms feature earthen counters as well as recycled sinks and doors. All fixtures are low flow. Gord created the cabinets on his side, Ann’s dad created his cabinets.

Showers on both sides are Tadelakt. Basically it is a lime plaster that is burnished with a smooth rock and then finished with an olive oil soap. Gord says it is not really hard work but it is tedious, taking about 4 days for each shower. Tubs weren’t installed as they use excessive water.

http://youtu.be/U71ejhpve4U

Net Zero Electricity

The couples electricity comes from a 2 kW grid tied solar array. They are net zero and sell excess electricity back to their utility.

A model made of the home showing the green roof and solar panels

Ann and Gord use renewable sources but really believe that the best way to conserve energy and electricity is through the lifestyle choices. It is a different relationship with energy and comes from realizing that energy comes at a big cost to our planet, people, communities and other living things. They are not hard done by and live as well as other families, they just realize that electricity is a gift and use it with respect to their environment.

The house uses 90% less electricity than the average home of its size and the families use 90% less water per person as well. They conserve electricity in two ways. The first is through lifestyle choices – simply choosing to have less stuff, meaning no dryer, dishwasher, microwave or toaster. They also use a laptop rather than a plugged in computer.

The other way is through efficiency. They use LED lighting throughout the house, path lighting so you don’t light up a room when you are not in it, corded rather than cordless phones, a DC powered Sundanzer chest fridge rather than a bigger upright fridge. Pumps, fridges and other systems in the house use DC power as efficiency is reduced when you convert from one power form to another. The laptop, TV, vacuum cleaner and blender run AC power. The home mechanical systems are extremely efficient as well.

When it comes to a cloths dryer they don’t want or even need one because of the way the home functions with moisture. You wash your cloths and if it’s winter time and even it has been raining for weeks, everyone has a cloths rack in their room or one in the mechanical room, you hang your cloths up in this house and twelve hours later they are dry.

Solar Thermal Combination System

Ann and Gord’s solar thermal system uses 60 evacuated tubes to heat water that heats their earthen floors, as well as provide them with domestic hot water. Heat from the tubes runs the hot water through inner core coils on a 120 gallon storage tank.

The system is designed so that if the floors don’t require heat but the boiler’s running, the heat will go through the upper coil and heat the tank up. Water goes both ways – they can pull heat out or put heat back in with a couple of check valves. Normally with a hydronic system you have a circulation pump and manifolds that are controlled by electronic zone control valves turned on and off by way of a thermostat. The couple got rid of the main pump and valves to eliminate phantom loads. If there is no heat required there is no draw.

Each thermostat a little solar circulating pump so when a thermostat calls for heat, a pump comes on, the valve opens, hot water runs through that zone. In the coldest day of the year, with the system running at full tilt, they use about 360 watts of power to control the whole system in that 24 hour period. This is a very small amount and is similar to leaving a 100 watt bulb on for 3.5 hours.

Winters in the area are mostly cloudy so you need to have some way of heating water without the solar thermal. An upper coil in the storage tank is used for heat takeoff (at least in the winter), pulling heat off the coil to run it through the floors. If there is not enough heat in the tank they can turn on the highly efficient wood gasification system. An hour will give another week of hot water. The system burns at about 1880 to 2000 degrees Fahrenheit, with an exit temperature of the flu of 160 degrees. The rest of the heat is then trapped into the water jacket tied into the water storage system (hydraulic) that runs through the floors of the home.

Living Roof

An example of a living roof

The couple wanted to do a living roof on their home but found buying one too expensive. They also thought the ones you buy have a lot of plastic and they really wanted to be able to install it themselves. They came up with their own design.

- The design starts with a waterproof membrane. They use a firestone apm membrane, basically it is like a really thick pond liner, but actually a roofing membrane. If you want your water to be potable you have to be aware of the materials you use. The one the couple ordered has no fire retardant in it. Not only is this important for the families but The Living Building Challenge does not allow fire retardants because of its potential health problems.

- Then there is a really thick polyethylene non-woven geo-textile, the same as the material used in highways and dams as well as landscape stabilization. This is called Armtech 400 and acts as a cushion and puncture resistant layer. It helps for root protection and acts as a drainage layer.

- On top of the Armtech 400 they have perlite, which you can get from the horticulture stores.

- A thin filter cloth follows bought from a plumbing supply store. That is your drainage layer. So as water comes down it, you have the ability to shear the water off underneath the living layer without losing your dirt.

- You need to have a material down that your roots can actually attach to so they don’t blow out in the wind. You can use straw, the couple used coconut husk matting. Again you can buy it from the same people that sell the geo-textile material as it is used in landscaping and is a landscape fabric. The material goes on and will rot in a period of 5 or 6 years. It then becomes compost.

- Then on top of that the couple uses a combination of pumice, leaf mulch and a bit of soil and that makes the growing media. Then the roof is planted with native plants.

The couple says that a more intensive roof can have a thicker growing medium but you would need more layers of materials and a thicker growing medium and you have to make sure your roof is engineered for the additional weight.

parts of the couples water system

Some of the benefits of a living roof start with its water filtration properties, pine needles or pollen can really goo up your water and they don’t get through. It works as habitat replacement, it is very beautiful, it makes it very quiet inside and it is fire resistant. If fire were to land inside you get a big poof from the grasses but there is nothing else to burn. The PV panels produce more efficiently because they stay cooler during the higher season.

The living roof works as mini water shed. When you think about rainwater collection you have to account for first flush diverting, taking care of pollen, pine needles, bird pooh and the living roof looks after that. The amount of filtration they have to do before storage is decreased and the water comes out clean, like a creek or a water shed.

A 10,000 gallon (37,854 litres) tank stores their rainwater and is further used for irrigation of the food gardens.

Grey Water

Ann and Gord grow their own vegitables and have a healthy garden fed by the grey water systems

Because the families make their own food they need about double what is calculated from their water meter so although they do collect rainwater they have to pull some out of the well. They have a goal of rehabilitating a man-made pond on the property that wasn’t holding water. The job involves diggin it out and adding more clay.

Four grey water systems water the many fruit trees and gardens surrounding the home.

One grey water is plumbed into the house so if the well were to go bad they can add a couple of filters, a UV sterilizer, and have potable water.

2 cisterns fill equally and are tied together at the bottom with an over flow at the top. Alternatively they can choose to have one overflow. Down the hill, they have another cistern to water the winter vegetable gardens.

No Waste Building

The couple showed us a special apple tree planted where they manufactured the house. This means the walls, floors, paints, insulation, plasters and everything was processed as well as the waste. Normally when a home is being built you would have a dumpster and take the waste to the landfill. The couple uses the tree as a front yard litmus test to prove that it is non toxic that’s symbolic of traditional building versus low impact building. They proudly boast that they produced almost no garbage in the build nor was waste was shipped into someone elses back yard or for future generations. The impacts are in their front yard because they can eat the fruits of their labours.

As wells as growing the vegetables the couple has honeybees saying that you need pollinators for growth.

Worms/Compost

The grey water that comes from the kitchen sink goes into a bin and then into a worm filter. The worms eat the bits of food acting like a surge tank or grease trap and turns it into worm casting, the best compost money can buy and they use that in the gardens. The water then goes to the very bottom of the hill to water trees there. Another grey water system drains from the laundry room and looks after the plum trees and raspberry bushes.

Kitchen Compost

Another system in the house feeds from an elbow off the bottom of the kitchen sink. You take the elbow off of one of your sinks and you put a sanitary Y in it with a knife valve or a day valve and bucket in it. When you open it up, the water goes into the bucket, you close it and the water can go back to the grey water system. The couple says it is really good when you are washing your potatoes or similar and is one of those $17 fixes you can put in your house that can be used to water plants in your house or balcony. It is important to remember to close the knife valve if you don’t want to mop up the floor.

Human Manure/Compost

The waste from the bathroom – human manure, goes to a compost pile. Even though the couple adds to the heap regularly you don’t smell much except for hot straw. The process is called thermophylic composing. When you have the right balance of carbon – feces and nitrogen (urine) – as well as wood shavings and kitchen scraps you have the perfect environment for thermophylic bacteria to thrive. When they thrive they produce a lot of heat and when they produce a lot of heat they essentially pasteurize the compost.

The couples adds to a pile for a year, let it go through its heating cycle and at the end of the year let it sit dormant for another year, letting time do its thing. After two years of composting the first thermophylic, and the second metaphysically, they send samples of the compost to a lab and they do a bacterial analysis of it, coming back completely food safe.

Shading

Trees on the western side of the house shade the home from the sun. The idea is to have a whole row that have solar features and are actually food on the western side.

Work Shop

A cob building created in a workshop

The couple’s work shop was their first cob building and is an engineered load bearing out building. They had never done cob before and we had to practice so this is what they did when we first moved into the trailer.

They build this one by foot, meaning that they mixed the clay, sand, straw by using their feet, and built using a handful of cob at a time, the traditional way, meaning it took a long time. The build took 600 buckets (5 gallon, 20 liter) of clay from a defunct pond and mixed that up with sand and 25 bales of straw.

Greenhouse

In the front area of the home is an earth sheltered green house the couple built. They cut the bank out and did a foundation footing consisting of rammed earth and tires. There is a concrete stem wall and behind the stemwall there is old foot thick dock foam, used for insulation .

The outside of the greenhouse has a built-in bench as well as a bread oven. This is a shady summer spot and it is a great example of comfortable as well as carbon neutral patio.

Chicken coup.

Even the chicken ccop has a green roof!

The couple’s off grid chicken coup is a mini version of the house. It has natural plaster, recycled materials and is fully insulated. The building has its own solar panels and a battery bank of used car batteries. A little DC timer on the side controls an led light in the winter and extends their laying hours. In the summer it controls a little 12 volt fan.

The coup features a living roof, and was the couples first. It is planted with native plants rescued from a local blasting site. They say it is spectacular in the spring as it is covered with wild flowers.

The roof acts as a mini water shed for the chickens rain water harvesting system. A recycled thousand liter tub automatically tops up a little stainless steel drinking bowl from an old sink. Whenever Ann empties their sink water – because chickens have a bad habit of standing the wrong way around – She empties that into their grey water system which in turn waters a fig tree, which will grow up and produce the figs for the chickens to eat, ones that land on the ground and figs for the family to eat. The chickens eat the bugs and the tree gives shade for them in the summer and protects them from predators as the areas has a lot of eagles and hawks and owls.

It is important to see how all of the systems are interconnected.

Living Building Challenge

The Living Building Challenge is an international green building rating system, that is the brainchild of Jason McLennan, CEO of Cascadia Green Building Council, and International Living Building Institute. This system is the greenest rating system internationally, whose focus is to strive to ensure the built environment is regenerative to the ecosystems that we share and live within. Ann and Gord’s home achieved Petal Certification in October 2010, and presently (as of Sept 2011) is the greenest home rated by the greenest rating system ever created.

When Ann and Gord heard about the Living Building Challenge they had already started building the house. The found the challenge had them written all over it and there are certain choices made that they would have made anyway.

The couple achieved 4 four of the 6 petals (12 of the 16 prerequisites) and has had their build called “The Greenest Modern Home in the World” from Jason McLennon, CEO of Cascadia Region Green Building Council.

They found it an interesting mix because they are not architects or engineers and they found it fun doing the paper work. It led to was a really good relationship with Cascadia Green Building Counsel. The 18 months of research in conjunction with Cascadia on the earthen performance of the walls included the thermal dynamics, moisture retention, the science as well as other things they wanted to accomplish anyway. The science report is 100 pages and its all grafts and technical data and shows how the mass walls perform. There is also a full energy analysis of the house with the solar thermal and solar photovoltaic.

The couple says that they really try to reduce our carbon footprint with every project. For the living building challenge they had to do a full carbon analysis on the house. The highest was the concrete foundation and the membrane on the living roof but when you take into account everything else on this piece of land plus all the habitat regeneration – this was a damaged site and the eco system is now much healthier – they actually built carbon neutral.

They were not allowed to have toxic materials in the house, called the materials red list and they were also successful in this regard.

The Living Building Challenge does not allow fire and you must be net zero, use no fossil fuels and the couples use a propane stove, with fire disqualifying them for net zero energy. But they would have needed a lot more solar panels to run electric panels for the full home. If they were to put in an air to water heat pump, basically it would cost about $40,000 to be net zero energy.

* The couple did not meet the following for the materials petal and Energy petal:

- PR04 – net zero Energy. They are net zero electricity but use a propane cook stove and use a wood gasification boiler to supplement the solar thermal, as part of a combination DHW and space heating (in floor hydronic). NO COMBUSTION allowed for the LBC although the family uses 90% less electricity per person than the average in their region.

- PR07 – responsible industry. We used 90% sustainable wood (80% recycled). Must be 100%

- PR08 – Appropriate Materials/Service Radius. Utilized bamboo matting for ceiling covering. Traveled too far.

- PR09 – Leadership in Construction Waste. They built the entire home without a dumpster and just biweekly domestic garbage pick up and recycling. 1 can every 2 weeks for two families AND building the house. However we did not document.

Cost

Finally, what the couple has done is to build an affordable home. The average cost to build a home in their area is $277 per square foot. A low end house is $160 sq ft. Their home came in at $148 sq ft. including $80,000 worth of sustainable energy systems. On top of that with those systems in place they don’t have monthly utilities bills. If they were to take the systems out and put in conventional heating and electrical the home would be down to about $110 sq ft.

What they would do different

And yet they would do things differently. They build cob homes for others and two of them a couple of summers ago. One house is a 1000 sq ft and load bearing cob on three walls and wood chip and cob on the fourth wall. They had all their wet plasters, it was -10 outside in the middle of winter, the wrong time to be doing plasters, the wrong time to be doing earthen floors and someone accidently knocked the breaker off for the heating system. And it was 7 days before they knew that the heating systems was not turned on. The temperature dropped 2 degrees centigrade in the house . Because of the change of the design and the way of approaching it functioned extremely efficiently, true passive.

The other house uses a a big sand bed under the house to dump excess solar hot water heat. When you have too much hot water during the summer you can dump it under the insulated slab and it stores it there and then you can run the pumps the other way in the winter and take the heat back. A mini geothermal. The bigger the temperature differential you have between one space and another space, the better the energy flow going out there.

What they found is that in the shoulder seasons, fall and spring, when the sun hits the southern portions of wall, the walls will go up 40 – 50 degrees centigrade. What happens is that all of a sudden the wall which is normally energy flow going this direction all of a sudden changes direction. Because of the nature of the mass wall, it is responding based on the temperature differential of the solar insulation, actually like a solar battery. It is very interesting to watch and very interesting to monitor. This house was a great learning opportunity. There is a lot we’ve learned from it that we can take to the next stage and that is what we are doing in our work. We are taking it to the next stage with other peoples houses as well as educating people.

Ann and Gord can now do a 4 foot lift in one day with any trimming. They have adjusted their technique so as to build high and let it splurge into its own shape and then they just hand form it. They understand that the mixture is going to do it anyway so they work with it.

Education and consulting

First change the dialogue, get people interested. Ann and Gord make their living with sustainable consulting and tours. One of the goals is to spend a third of the time working, a third volunteering for the community and a third doing our own thing. They have recently gotten to that point and spend much of their time educating groups and individuals as well as building cob homes for others and teaching people how to work with nature, not against it.